NPG- Nano Paper Guard

Hydrophobic Nano Coating for Preservation and Protection of Paper and Cardboard

Water-Based Barrier that Repels Water and Moisture

Problem Description:

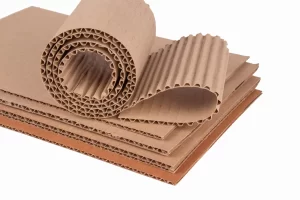

Global industries use tens of millions of tons of paper and cardboard every year, primarily for packaging and storage, to protect and preserve goods for as long as possible, and/or to maintain freshness and extend shelf life in the case of agricultural products, from the time of packaging, through storage to use.

Demand for the essential raw material of paper and cardboard has increased due to increased worldwide trade, the necessity to improve the shelf life of many products for storage, and the demand for longer preservation has contributed and continues to contribute to the unfortunate outcomes of increasing the rate of global air pollution by deforestation, lower the capacity to convert CO2 to oxygen, and ultimately, damage to our quality of life.

It is a well-known issue that cardboard and paper packaging deteriorate and degrade while carrying goods to customers, from the factory’s packaging stage, through sea, land, and air transportation to final delivery and during storage due to water and moisture damage that causes the poor result of corrosion to electrical/electronic/mechanical equipment, damage to wood products from water absorption, causing swelling and mold, destruction of leather and fabrics, increasing moisture and mold in the food and agriculture industries, and destruction of countless products packaged in cardboard and paper long before shipments have arrived at their destination.

Another aspect is the short life span of packaging products based on paper and cardboard caused by accelerated wear and tear, which leads to three main problems:

- An increase in paper waste, requiring an increase in energy and manpower for handling and transporting to recycling and waste plants

- Extra costs due to an increase in the need to replace the packaging, early or unforeseen destruction, which results in more needless deforestation

- An increase in the weight and volume of cardboard and paper to increase protection, resulting in extra costs for purchasing, shipping, and storage in terms of quantity and money.

Due to this, the cardboard and paper industries worldwide have recently sought solutions to these issues. Although many techniques, such as wax, silicones, solvents, “oil paper,” and endless nylons, are already in use, the current solutions are, in the best case, insufficient and, in the worst case, only partially effective.

NPG’s Solution:

To address these issues, a special formula was created, an intellectual property of Nano Coatings Ltd. offering a cutting-edge nanotechnology product as a unique and advanced solution for the paper and cardboard industry – a natural, odorless, transparent, ultra-thin, water-based, and environmentally friendly coating protects and preserves paper and cardboard. NPG provides an excellent coated surface with extraordinary water-repelling qualities (hydrophobic lotus effect), has a special rate of regular “breathing,” outstanding UV resistance, and does not change color.

The exterior resistance of paper and cardboard to water, moisture, and seawater is strongly enhanced with an NPG barrier as a stable, invisible coating. Other silicone, wax, Teflon, and solvents materials swiftly degrade and disappear when exposed to sunlight, radiation, salinity, and soot! Additionally, if they are wrapped with plastic, it is often not correctly sealed, let water and moisture through, and eventually rip or wear out.

NPG creates a high contact angle and, thus, an effective barrier that protects and enables rapid disposal of water, rain, seawater, salinity, and soot and repels moisture efficiently. However, it is not designed for standing water or underwater environments.

In this, the total advanced NPG properties have great significance in the protection and preservation of paper and cardboard:

- A) During transit, by land, sea, and air, as a necessary component to safeguard product packaged

- B) During storage, while preventing moisture from causing weathering, mold, and other damage that destroy the paper/cardboard and thus fail to safeguard the product they are protecting.

Typical Uses:

Sea, air, and land shipping companies; cardboard boxes for protecting sensitive/electrical/electronic/computer equipment; factories and manufacturers of all kinds; long-term storage; reducing corrosion and wear damage; protecting agricultural produce; fresh and dry food factories; military needs; in hospitals, and anywhere there is paper and cardboard intended for preservation and protection of packaged products.

16 Reasons Why NPG:

- Protects sensitive equipment and finished products goods while being transported and stored

- Stabilizes and safeguards cardboard and paper against moisture penetration and delays and repels the effects of rain and seawater

- Reduces mold and damage to agricultural produces and food packaging

- Reusable packaging due to extending the life of the cardboard results in significant cost savings

- Savings in manpower required for handling and transportation, as well as materials are necessary for wrapping

- Excellent water and moisture repellency that prevents absorption

- Reduced cardboard thickness results in cost savings of up to 50% and a reduction in the weight of the cardboard/packaging!!

- Eliminates or reduces the use of wax, silicones, Teflon, nylon, and other traditional protecting means

- Contributes to reducing deforestation, preserving the environment, reducing waste, and removing or recycling costs

- Strong UV resistance – inhibits fading

- Does not change color – invisible, odorless, and colorless

- Eco-friendly, water-based, natural element/material

- Easy application by manual spraying, airless, or in an HLPV factory system

- Enables printing

- Dries at room temperature, requiring no additional energy

- Once completely dry, the surface actively repels water

Outstanding cost-effective per Sq. /m, due to the very small using material in the process

Coverage: 5-10 m2/liter. Depending on absorbency and type of surface.

Packaging: 3.8 liter gallon | 20 liter gallon | 1,000 liter

Storage: in a cool and shaded place at 3-40° Celsius for up to 1.5 years

Application instructions:

- Clean the surface thoroughly from dirt and dust.

- . Spray a thin, one-coat, and overlapping layer from a distance of 15 cm to disperse a mist cloud until entirely wet. For savings and effective dispersion, it is recommended to use an original Nano-Coating sprayer!! Or HLVP system in industrial production lines).

- . Wait until fully dry. Drying time depends on the ambient temperature and humidity. The coating will become water-resistant once dry. For full resistance – wait 24 hours.

- . Although the product is water-based – use suitable protective measures such as goggles, gloves, etc. (read the MSDS carefully before use).