NC-18 Glass Nano Coat barrier

Ti-10H hardness. Transparent hydrophobic coating protects from micro-scratches, helps preserve glass, and repels dust

What is NC-18?

NC-18 is perfect optimize nanoparticles coating barrier in a visible size range of about 25-50 microns and is designed to maintain visibility, provides micro-scratch protection, UV protection, hydrophobicity, dust reduction, making the surface to be clean as well as very easy for cleaning using only water and microfiber cloth.

NC-18 is a glass transparent protective layer that excels in its ability to “fill” the pores surfaces without compromising the transparency and transmission of light, thereby preserving, protecting and prolonging the life of the glass against the phenomenon of turbidity because of environmental pollutions attacks and natural wear.

NC-18 will give the surface excellent properties of massive chemical resistance, improved resistance for soft abrasion and micro-scratches, water mud and ice repellent, hydrophobic properties, UV protection as well as anti-graffiti protection.

What is it for?

- Glass industry.

- Renovation and protection of buildings & malls that are external and internal covered with glass panels.

- Kitchen and bath products such as:

sinks, refrigerators, kitchen surfaces, hospital accesso ries, showers, etc. - Sales counters, display cases, railings, elevators, escalator etc.

- Jewelry industry, sculptures and Judaica.

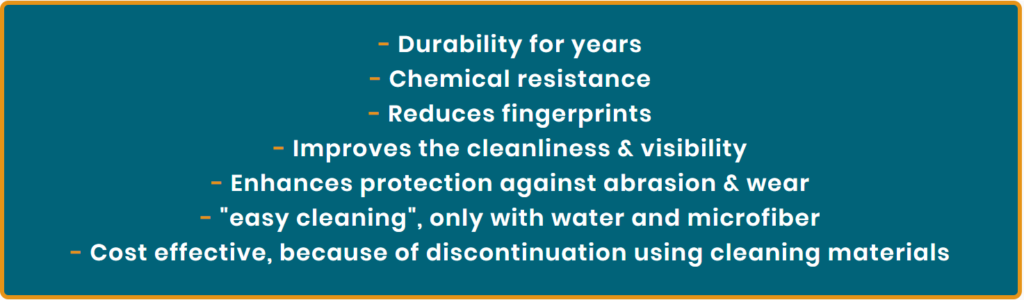

The protection advantages:

- Strengthens the protection against erosion, wear, turbidity (whitening) of the glass, thereby extending the object’s lifespan.

- Improves the object’s appearance with its initial properties for a very long time.

- The hydrophobic and oleophobic properties (water and oil-repellent) do not allow dirt, scale and contaminants:

a) To adhere to the object and thereby facilitate easy removal with water only, and economize on the cost of oil, chemical and acid removers;

b) They give and strengthen the general level of surface sterility and cleanness. - Reduces fingerprint traces and allows their easy removal.

- Excellent resistance to erosion as a result of unique adherence capability.

- Strong and stable UV durability allows resistance for many years (varies according to the environment and the type)

- Stable chemical resistance to almost all standard household or industrial cleaning products.

- Helps to preserve the surface also in harsh environmental conditions of humidity and saline humidity.

Very attractive cost per square meter!!

The product properties:

- Dilution: Not required. The product is ready for use.

- Drying/hardening mechanism: natural, without external means. However, the hardening time can be accelerated with IR lamps or a hot air system with a temperature of 60°C for up to an hour and in an environment with maximum relative humidity of 50-70%.

- Sheen level: full transparency.

New Terminal Project – Ben Gurion-Airport

Method of application:

- Clean well, wash off dirt and dust and any other contaminant with clean water and soap.

- Dry well with a cloth or electrical means providing hot air.

- Protect with adhesive tape on the surfaces that are not designed for coating such as: aluminum rails, plastic parts etc

- For deep cleaning use Nano-Z Coating’s CW-101 with nonwoven or microfiber cloth and dry well.

- Drip 5-6 drops each time on the enclosed sponge and apply in straight and overlapping lines in one direction without applying pressure.

- Wait only 1-1.5 minutes for the first hardening. Then, smooth the surface and remove any residue. Use high quality microfiber, applying light pressure, with rotating movement to achieve a complete shine.

- After 2-3 minutes – apply a second coat as described above. (Warning – a second coat can be applied up to 5 minutes from the end of application of the first coat. If the time was exceeded do not apply a second coat and remain with one coat. In such a case the protection will be less.)

- Drying time for contact: 1 hour from conclusion of application of the second coat.

- Full hardening: 48 hours.

- Final hardening and for tests : after 72 hours

- The surroundings and the tools can be cleaned with white spirit and only as long as the product has not yet dried.

– In industrial use – low air pressure (airless with fine nozzle of 0.25-0.3 or less).

Coverage Capability:

100-140 Sqm/liter per one coat – depending on the surface texture and the manner of application.

Final coating thickness 25-50 nm.

* Important remark: coating with additional layers will give the surface greater protection.

Packaging:

DIY KIT: 1 liter; 3.8 liters; 19 liters.

Storage: